The gasoline isomerization unit catalyst is one of the most important and vital materials used in the oil refining industry, designed to improve gasoline quality and increase the proportion of high-octane hydrocarbons. These catalysts play a key role in isomerization units, helping refineries produce high-quality fuels that comply with environmental standards. Oil and petrochemical industries seek to purchase high-quality gasoline isomerization unit catalysts to enhance the efficiency of their gasoline production units and maximize process yields.

Application of the Isomerization Unit Catalyst

The isomerization unit, part of modern refineries, converts light linear hydrocarbons (n-paraffins) into branched hydrocarbons with a high octane number. This process produces higher-quality gasoline, improves combustion characteristics, and reduces pollutant emissions. The gasoline isomerization unit catalyst accelerates isomerization reactions and increases the conversion efficiency of hydrocarbons through its active structure.

This catalyst is effective on compounds such as pentanes, hexanes, and heptanes. By using this catalyst, linear compounds are converted into branched forms, significantly increasing the octane rating of gasoline. This process plays a crucial role in producing environmentally compliant, standard gasoline.

Technical Features of the Catalyst

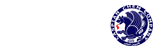

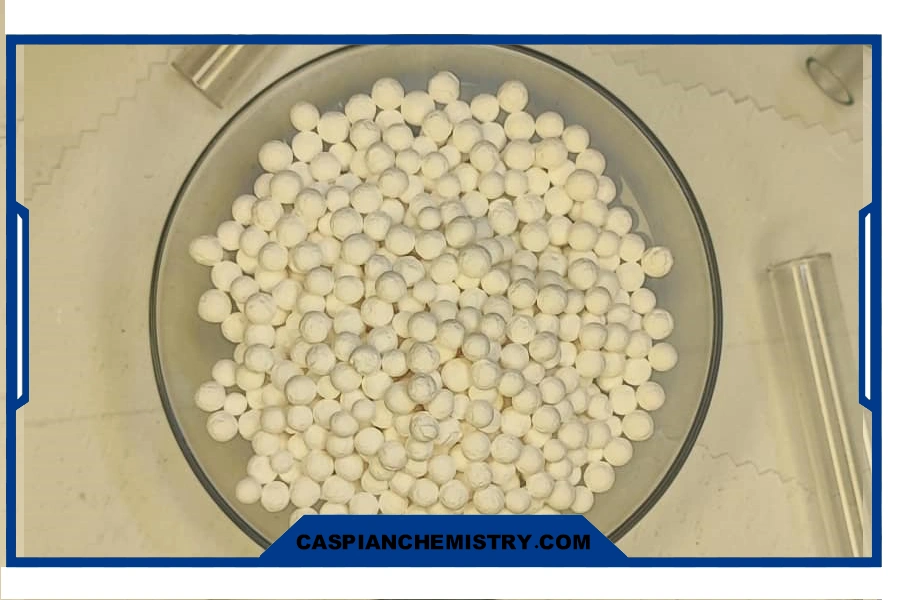

A key feature of the gasoline isomerization unit catalyst is its high active surface area and ability to perform isomerization reactions rapidly and efficiently. Its uniform porous structure ensures optimal hydrocarbon flow distribution within the unit, minimizing the risk of clogging or reduced performance.

The active metals in the catalyst are stabilized on a durable and stable support, enabling effective operation under refinery temperature and pressure conditions. The high chemical and thermal resistance of the catalyst ensures that the isomerization process proceeds with minimal efficiency loss over time, increasing the unit’s service life.

Purchase and Sale of the Isomerization Unit Catalyst

Oil and petrochemical industries can procure gasoline isomerization unit catalysts from reputable suppliers. Purchasing from trusted sources ensures the product has industrial-grade quality, precise technical analysis, and stable performance in isomerization units.

Furthermore, selling gasoline isomerization unit catalysts in industrial and standard packaging allows continuous and reliable supply for large projects and industrial units. Complete technical information, guidance on catalyst selection, and optimal operational conditions help industries ensure efficient performance and maximize the catalyst’s service life.

Advantages of Using the Isomerization Unit Catalyst

Using the gasoline isomerization unit catalyst offers several benefits, making it a key choice for refineries:

Increased Isomerization Efficiency: Converts linear hydrocarbons to branched forms with high yield, reducing feedstock loss.

Improved Gasoline Octane Number: Produces higher-quality fuel compatible with environmental standards.

Operational Stability: High resistance to heat, pressure, and chemical compounds in the oil stream.

Extended Unit Lifespan: Reduces the need for frequent catalyst replacement and lowers maintenance costs.

Energy Optimization: Accelerated reactions reduce energy consumption and improve economic efficiency.

Conclusion

In summary, the gasoline isomerization unit catalyst is a critical and essential product for refineries and the oil and petrochemical industries. Its use increases isomerization process efficiency, produces high-octane gasoline, reduces pollutants, and enhances overall unit performance.

Industries can secure high-quality gasoline isomerization unit catalysts with verified technical analysis and stable performance, ensuring optimal unit efficiency. The sale of these catalysts in industrial-standard packaging ensures continuous and reliable supply for large projects and continuous operations. With its unique features, high active surface area, and resistance under harsh operational conditions, this catalyst is one of the most important materials for producing high-quality, standard gasoline, helping industries operate processes efficiently, safely, and economically.