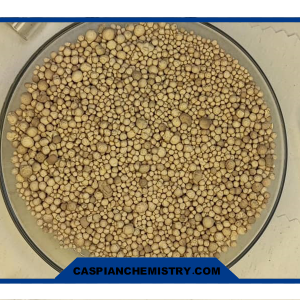

Gas Sulfur Removal Unit Catalyst 13X

The 13X gas sulfur removal unit catalyst is an essential and advanced product in the oil, gas, and petrochemical industries, designed to remove sulfur compounds from gas streams. Due to its high efficiency and unique technical properties, it plays a critical role in improving the quality of natural gas and petrochemical products. Many industrial units turn to purchasing the 13X gas sulfur removal catalyst to enhance the efficiency of their desulfurization processes and comply with environmental standards.

Applications of 13X Gas Sulfur Removal Catalyst

The 13X catalyst is primarily used in natural gas and process gas desulfurization units. The main goal of these units is to reduce sulfur compounds such as H₂S, mercaptans, and other sulfur species, which otherwise can cause equipment corrosion, reduce product quality, and create environmental problems. Using this catalyst ensures high-efficiency sulfur removal with optimal speed and minimal energy consumption.

Thanks to its porous structure and high surface area, the 13X catalyst effectively adsorbs and reacts with sulfur compounds. This property enables the gas desulfurization process to operate at high efficiency, maintaining consistent performance and achieving the desired gas quality.

Technical Features of 13X Catalyst

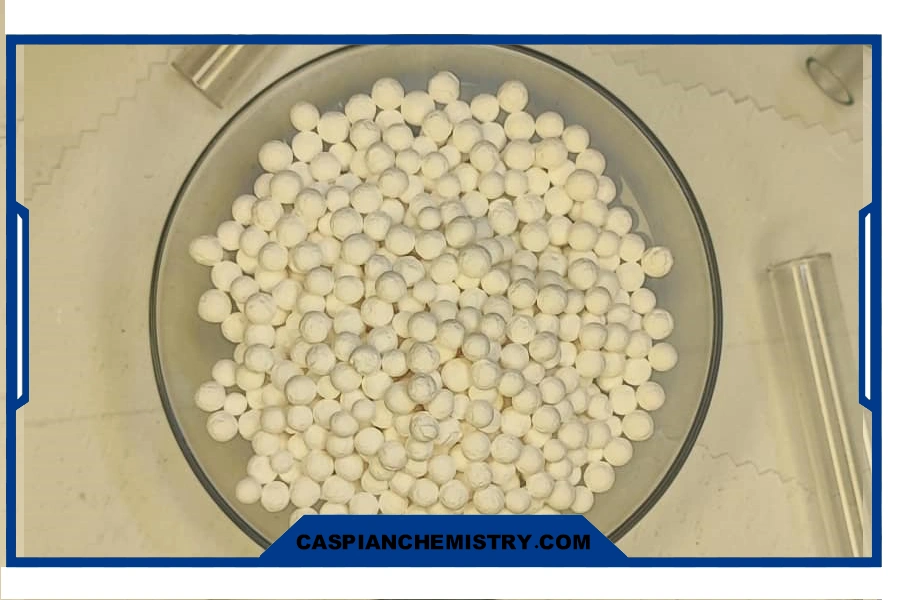

One of the key features of the 13X gas sulfur removal catalyst is its well-ordered crystalline structure with controlled porosity. This structure provides a large contact surface between the catalyst and sulfur compounds, enhancing the speed and efficiency of desulfurization reactions. High chemical and thermal resistance ensures stability under harsh operating conditions and high pressures, offering a long service life.

Another important feature is the uniform distribution of active sites and rapid sulfur compound adsorption, minimizing the risk of blockage and efficiency loss. These characteristics make the 13X catalyst one of the most reliable and widely used options for industrial desulfurization units.

Purchase and Supply of 13X Catalyst

Oil, gas, and petrochemical industries can procure the 13X gas sulfur removal catalyst to meet operational needs. Purchasing from reputable suppliers ensures industrial-grade quality, precise technical analysis, and high operational performance.

Moreover, 13X catalyst is supplied in industrial-standard packaging, enabling continuous and reliable supply for large-scale projects and industrial units. Providing full technical information, consultancy on operational conditions, and maintenance guidelines helps industries ensure optimal performance and extended catalyst lifespan.

Benefits of Using 13X Catalyst

The 13X gas sulfur removal catalyst offers numerous advantages, making it a key component in desulfurization units. Benefits include:

Increased sulfur removal efficiency

Improved quality of produced gas

Reduced equipment corrosion

Lower maintenance costs

Extended unit lifespan

Its technical properties, including high surface area, chemical and thermal resistance, and consistent performance, allow the 13X catalyst to operate reliably over time without efficiency loss. This is particularly important for oil and gas industries that require clean and standardized gas supply.

Conclusion

In summary, the 13X gas sulfur removal catalyst is a vital product for the oil, gas, and petrochemical industries, significantly enhancing desulfurization unit performance. Using this catalyst increases sulfur removal efficiency, reduces pollutants, protects equipment, and improves the quality of the final product.

Industries can procure high-quality 13X catalyst with verified technical analysis and ensure optimal unit performance. Additionally, industrial-standard packaging and continuous supply enable reliable provision for large-scale projects and continuous consumption. With its unique properties, high surface contact, rapid adsorption capability, and resistance to harsh operational conditions, the 13X catalyst is one of the most important materials in gas desulfurization units, helping industries perform their processes efficiently, safely, and economically.